Packaging plays a key role in the success of your company. It shows the public what you sell, and how good you are at it. That’s why packaging plays an important part in the functioning of a company. You need to have equipment that is reliable, durable and easy to use.

Various types of packaging equipment will help you meet the needs of your business. Here’s everything you need to know about packaging equipment, from different kinds of packaging machinery to advantages and disadvantages to costs and benefits.

What is packaging equipment?

Packaging is a way of protecting products so they arrive in good condition. It involves using materials, colours, and techniques to create a package. Packaging can be used for food and beverages, cosmetics, pharmaceuticals, household supplies, and many other products.

Packaging often communicates the qualities of a product. A clear package lets you see what’s inside, so your customer knows exactly what the product is and how it works. A colourful package can make the product more appealing.

Types of packaging equipment

There are many types of packaging equipment available in the market. Some of them are discussed below.

Heat seal machine – Heat sealing is the most common sealing method. Heat sealing is done by applying pressure between the sealing roller and the sealing film through an applicator. It produces a heat-sealed seal, which produces a perfect finish with no air bubbles on the surface of the packaging. Heat sealers are used for heat transfer printing, bar-coding, and labelling. Heat sealers are available with various types of applicator rollers and printing rollers.

Pressure seal machine – Pressure seal is also an example of a thermo-mechanical method. It is a very common method used to seal plastic packaging. It is controlled by a computer and it uses a sealing machine to apply pressure between the sealing roller and the sealing film through an applicator. It also produces a heat-sealed seal, but it is not as perfect as that of a heat seal.

Roll-to-roll manufacturing is the most common method of producing film and paperboard. The process involves cutting the materials into sheets and then wrapping them into a roll. It can be used to produce different types of packaging.

Off-line packaging equipment – In a traditional packaging operation, all the activities happen on-site. However, these days, companies are getting ready to launch products online. To meet the demand, you need packaging equipment, which can be produced on demand. You can use packaging equipment, which is produced offline, to produce your packaging.

Types of packaging equipment

Packaging machinery can be broken down into a few different categories, depending on the type of product being packaged. Some of these categories include: There’s also the subcategory of specialised packaging equipment, which we’ll cover later in the post.

Wrap and wrap machines

Wrapper machines are also known as “wrapper’ or “wrap/wrapper” machines. They’re used to apply a single layer of plastic film to a product and seal the edges. Wrapper machines generally come in two forms: automatic and manual.

Automatic wrappers use a film fabricating machine to produce a continuous strip of film with a peeler or punch that tears off a piece of film. Manual wrappers use a wet fabricating machine to produce a continuous strip of film that is then pulled off manually by the operator.

Bagging and branding machinery

Bagging and sealing machines are used to apply a layer of synthetic plastic film to a product and close the bag. This layer of the film serves as a barrier to protect the product inside from being damaged if the bag is broken. Branding machines are used to apply a permanent or semi-permanent logo to the bag. This can be done either manually or with a branding gun.

Conveyor belt, pallet, and stacker machines

Conveyor belts, pallets and pallet-sorting machines are used to move products from one storage location to another. They generally come in two forms: belt and disc. Belt conveyors are the most common type. They’re simply a spindle with a string on them that spins as the spindle runs underneath.

Disc conveyors use a circular path and a pair of rollers to move products from one location to another. Pallet-sorting machines are used to sort products by size and shape so they fall onto appropriate pallets.

Sealers and tape dispensing machinery

Sealing machines are used to apply a synthetic seal to a product. Bag sealers are used to apply the common bag seal to open-top bags. Roll sealers are used to apply the common roll seal to closed-top bags. Roll sealers are one of the most common types of packaging machines.

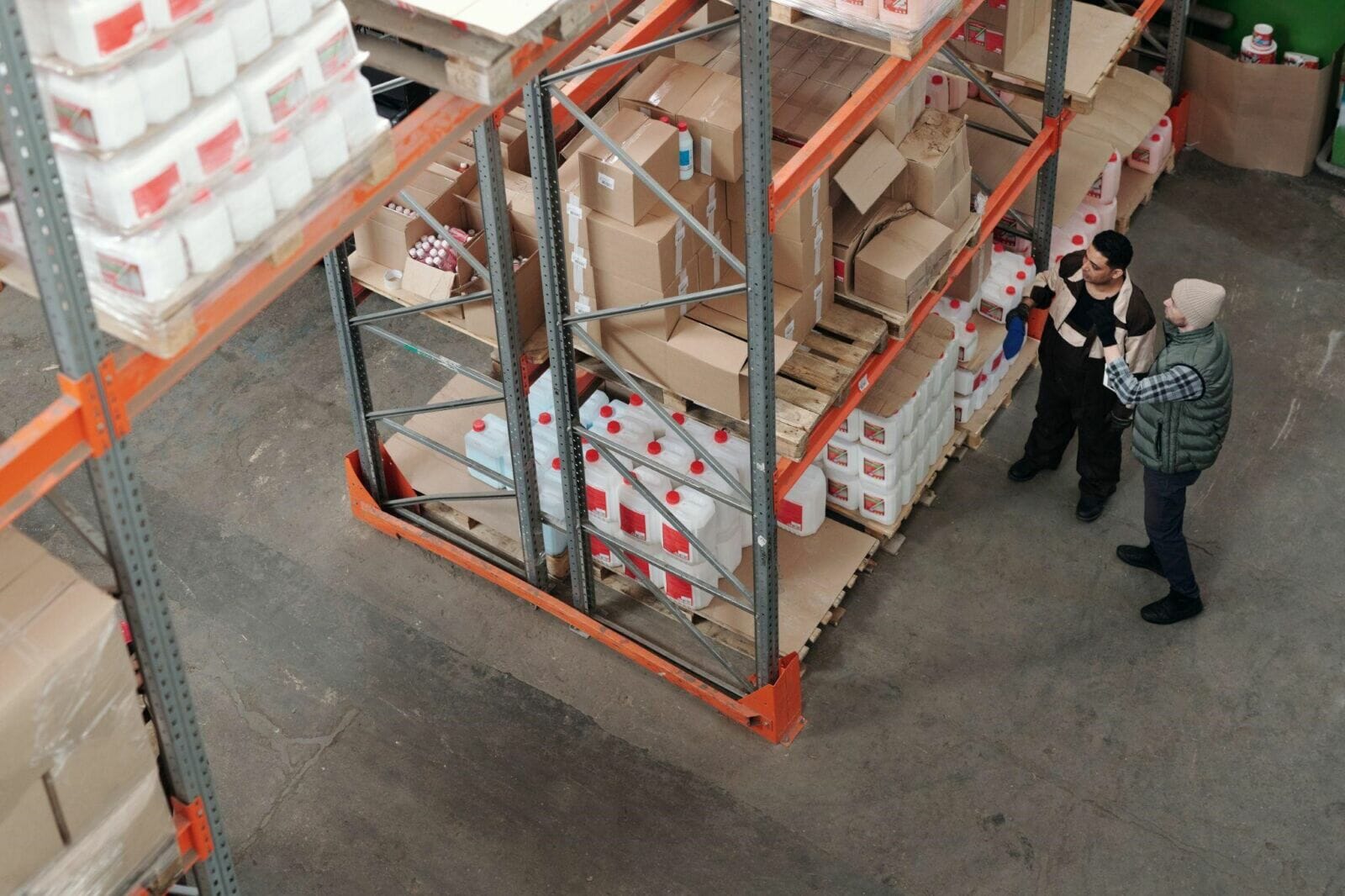

Handling and storage equipment

Handlers are the machines that move products from the storage location to the customer location. High-rate dosing machines are generally used to apply a high-dose (or direct-dispense) method where the customer opens the dispenser and places the product directly onto the shelf or in the customer’s cart.

Hose-end dispensers are used to apply dispensing methods like high-dose and pull-dispense methods where the customer pulls the hose out of the dispenser and walks to the product they want.

Conclusion

Packaging plays a key part in the functioning of your business, so you need packaging equipment, which is reliable, durable, and easy to use. Packaging equipment is manufactured to provide quality service and perform under harsh environmental conditions.

Various types of packaging equipment will help you meet the needs of your company. The most commonly used equipment includes heat seal machines, pressure seal machines, roll-to-roll machines, and film and paperboard packaging machines.

Packaging equipment can be tricky to figure out, but once you have the basics down, it’s easy to work with it. It’s a fun process to get into, and there are so many possibilities for creativity. When you’re done with all of this, you’ll have a better idea of how to get started with your own company, and you’ll have some great equipment too!